Environmental Remediation in Canada & North America Through Advanced In-Situ Techniques

At SCG, we are specialized environmental remediation contractors focused on the rehabilitation of industrial sites and Brownfields (previously developed land that is not currently in use due to contamination). We utilize state-of-the-art in-situ remediation technologies. “In-situ” simply means we treat the contamination in place, without the need to dig up tons of soil or disrupt your daily operations.

Our innovative methods address soil and groundwater contamination directly at the source. By employing techniques such as Multi-Phase Vacuum Extraction (MPE), Soil Vapour Extraction (SVE), and Air Sparging, we target and eliminate pollutants like petroleum hydrocarbons, solvents, and Volatile Organic Compounds (VOCs).

SCG’s approach ensures that your site’s remediation objectives are met efficiently, restoring the environment while minimizing the impact on business operations and surrounding areas.

Learn more about our Contaminated Site Remediation Technologies:

Multi-Phase Vacuum Extraction (MPE)

Simultaneous Recovery of Groundwater & Soil Vapours

Multi-Phase Vacuum Extraction (MPE), often referred to in the industry as bio-slurping, is a high-efficiency dual-phase extraction system. It extracts contaminants in both aqueous (groundwater) and vapour (gas) phases simultaneously using high-vacuum pumps and liquid air separators.

The system is installed using pre-existing well infrastructure or via subsurface piping. It is capable of recovering a variety of industrial contaminants immediately after commissioning. This in-situ extraction technique is highly adaptable for complex site conditions where rapid recovery is required.

Effective media

Soil & Groundwater

Targeted contaminants

Hydrocarbons, Light Non-Aqueous Phase Liquids (LNAPLs)

Removing Light Non-Aqueous Phase Liquids/Floating Contaminants (LNAPLs)

MPE is most effective with volatile chemicals and low-viscosity Light Non-Aqueous Phase Liquids (LNAPLs). In simple terms, LNAPLs are contaminants like gasoline or heating oil that are lighter than water and “float” on top of the groundwater table.

MPE relies on subsurface airflow to extract volatiles while simultaneously mobilizing these floating liquids. It is a powerful remediation technology that allows us to manipulate groundwater elevation, applying a significant vacuum gradient to “slurp” up pollutants that would otherwise remain trapped in the soil.

Soil Vapour Extraction (SVE)

Remediation of Volatile Contaminants in the Vadose Zone

Soil Vapour Extraction (SVE) is a proven process designed to remove volatile contaminants from the Vadose Zone. The Vadose Zone is the “unsaturated” layer of soil that sits above the groundwater table but below the surface.

The SVE system consists of a vacuum pump connected to recovery wells, which creates a vacuum within the soil pores. This pulls toxic vapours out of the soil before they can migrate further or enter buildings (vapour intrusion). SVE technology allows for the direct recovery of contaminants while also adding oxygen to the soil, which augments biological degradation (naturally occurring bacteria eating the contaminants).

Effective media

Soil

Targeted contaminants

Volatile Organic Compounds (VOCs) such as Benzene, Toluene, Ethylbenzene, and Xylenes (BTEX).

Effective Removal of Soil Contamination

When assessing SVE applicability at a site, optimal targets are volatile and easily degradable chemicals. Once removed from the subsurface, these vapours are treated above ground using an oxidizer or vapour-phase carbon vessels.

SVE is highly effective in porous soils (like sands and gravels) where airflow is maximized. However, it is generally not applicable for contaminants located below the groundwater table. Soil Vapour Extraction remains a cost-effective solution for in-situ treatment where contaminants are trapped in the dry soil layers above the water line.

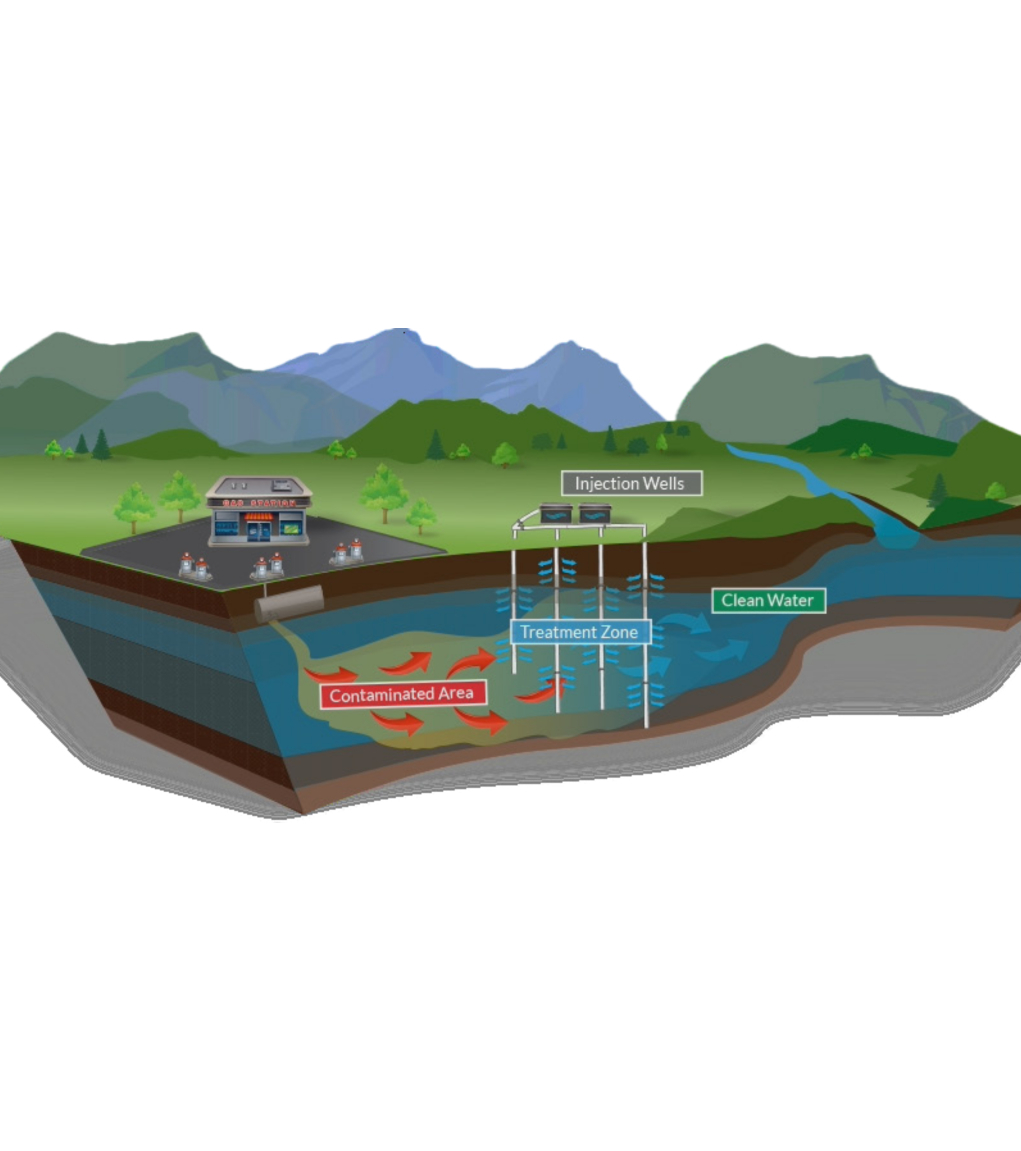

Air Sparging

Groundwater Volatilization & Bio-Augmentation

Air Sparging involves injecting pressurized air directly into contaminated groundwater. This creates bubbles that strip Volatile Organic Compounds (VOCs) out of the water and drive them upward into the Vadose Zone through a process known as volatilization (turning liquid contaminants into gas).

Once these contaminants enter the unsaturated soil above, they are captured and removed using an SVE system.

In addition to physical removal, air sparging increases bio-augmentation. By flooding the groundwater with oxygen, we create an ideal environment for native bacteria to thrive. These bacteria then actively break down the remaining pollutants, significantly speeding up the cleanup process.

Thermal Enhancement for Difficult Sites

To further optimize remediation, thermal enhancement has proven effective for mobilizing stubborn contaminants. SCG has successfully utilized heat from post-treatment exhaust streams, re-injecting it back into the subsurface. This warms the soil and groundwater, making thick contaminants flow easier and increasing mass recovery rates.